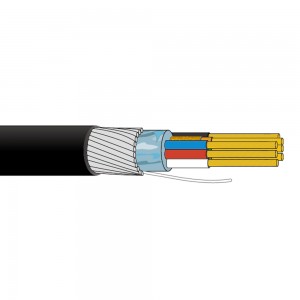

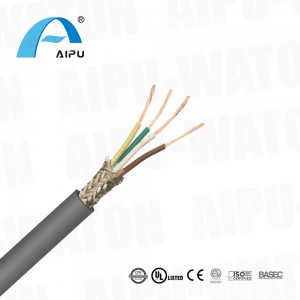

High-Flex Tinned Copper Braided Screen Control Cable rau Drag Chain Twisted Pairs Waterproof PVC Insulated Copper Hlau

CABLEKev tsim kho

Tus cojTooj liab liab, ntxiv nplua hlau conductors, IEC 60228 class6

Rwb thaiv tsevtshwj xeeb sib xyaw PVC rwb thaiv tsev,EN 50525-2-51

xim: ≤0.5mm² Xim core: xim av, dub, xiav, ntshav, liab, txiv kab ntxwv;

≥0.5mm² Dub core dawb tooj, ntau tshaj 3 cores nrog daj thiab ntsuab av xaim

Screened Bare / tinned tooj liab braiding, kev pab them nqi≥70%

Sab nrauvCov khoom siv tshwj xeeb PVC, xim: dub (RAL9005) grey (RAL7001) txiv kab ntxwv (RAL2003)Hom TM5 rau DIN VDE 0207 -363 -4 - 1 / DIN EN 50363 -4 - 1

Cov khoom hluav taws xob ntawm 20 ° C

Nominal voltage ≥0.5mm² 300 / 500V

Test voltage tub ntxhais / tub ntxhais 4000 V AC

Neeg kho tshuab khoom

Khoov cycles ntau tshaj 10 lab lub sij hawm

Tsav ceev 3m / s

Torsional stress TW-0 (5000 cycles ntawm ≥ +5 ° C)

TW-1 (2000 cycles ntawm ≥ -20 ° C) ± 150 ° / m ntawm 1 kiv puag ncig ib feeb

FlammabilityFlame retardand acc.Rau IEC 60332-1-2 Resp.VDE 0482-332-1-2

ATXOJ CAI

Haum rau qhov chaw ib puag ncig xws lidej pov thawj, roj tsis kam,UV tsis kam, huab cua tsis kam, txias tsis kam, hnav tsis kam, tiv taushauvib tug tej yam sab nraud mechanical quab yuam zoo electromagnetic yam ntxwv (kev cuam tshuam khawb,thiabinstallation nyob rau hauv reciprocating tsab ntawv tsa suab, tshwj xeeb tshaj yog nyob rau hauv kev lag luam ib puag ncig ntawm nquag bending zaus, xws li niaj hnub mechanical txheem qhov chaw nyob rau hauv lub saw thiab logistics system, tswj system, mechanical automation system.CNC tshuab cov cuab yeej, cov khoom siv hluav taws xob, khoom siv siab, ntoo pob zeb machinery, iav thiab qhov rais machinery, txhaj tshuaj molding tshuab, machinery (tib neeg) tes, siv machinery, hnyav machinery Hoobkas, tsheb tsim, nqa thiab thauj khoom, tsis siv neeg warehouse, wharf, hluav taws tsheb thauj khoom thiab lwm qhov chaw sab hauv tsev thiab sab nraum zoov yuav tsum tau tiv thaiv qhov chaw.

DIMENSION

| Tus naj npawb ntawm cov coresx ntu ntu ntu | Sab nraud txoj kab uas hla | Tooj Index | Qhov hnyav |

| mm² os | mm | kg/km | kg/km |

| 2 X 0.5 | 5.2 | 9.6 ib | 30.7 ib |

| 3g 0, 5 | 5.5 | 14.4 ib | 39.2 ib |

| 4g 0, 5 | 6 | 19.2 ib | 48.5 ib |

| 5g 0, 5 | 6.5 | 24 | 58 |

| 7g 0, 5 | 7.7 | 33.6 ib | 79 |

| 12g 0, 5 | 9.2 ib | 57.6 ib | 121.1 |

| 18g 0, 5 | 11 | 86.4 ua | 177.9 ib |

| 25g 0, 5 | 13.3 | 120 | 250 |

| 2 x 0.75 | 5.6 | 14.4 ib | 37.9 ib |

| 3g 0.75 ib | 6 | 21.6 ib | 49.4 ib |

| 4g 0, 75 | 6.5 | 28.8 ib | 61.5 ib |

| 5g 0.75 ua | 7.1 | 36 | 74.5 ib |

| 7 g0,75 | 8.5 | 50.4 ib | 105.6 ib |

| 12g 0.75 ib | 10.3 | 86.4 ua | 163.3 ib |

| 18g 0.75 ib | 12.2 | 129.6 ib | 239 |

| 25g 0.75 ib | 14.8 ib | 180 | 334.8 ib |

| 2 X 1.0 | 5.9 | 19.2 ib | 43.1 ib |

| 3g 1.0 | 6.3 | 28.8 ib | 56.5 ib |

| 4g 1.0 | 6.9 | 39 | 71.3 ib |

| 5g 1.0 | 7.5 | 48 | 86.2 ib |

| 7g 1.0 | 9 | 67 | 122.3 ib |

| 12 G 1.0 | 10.9 | 115.2 ib | 190.3 ib |

| 18g 1.0 | 13.2 | 172.8 ib | 285.4 ib |

| 25 G 1.0 | 15.7 ib | 240 | 391.2 ib |

| 2 X 1.5 | 6.5 | 28.8 ib | 55.6 ib |

| 3g 1.5 | 6.9 | 43.2 ib | 74.5 ib |

| 4g 1.5 | 7.6 | 58 | 94.7 ua |

| 5g 1.5 | 8.5 | 72 | 119.3 ib |

| 7g 1, 5 | 10.3 | 100.8 | 169.5 ib |

| 12 G 1.5 | 12.3 | 172.8 ib | 263.9 ib |

| 18 G 1.5 | 14.9 Nws | 259.2 ib | ib 395.1 |

| 25 G 1.5 | 17.9 ib | 360 | 549.4 ib |

| 3g 2.5 | 8.4 | 72 | 115.6 ib |

| 4g 2.5 | 9.3 | 96 | 148.2 ib |